- ISO 9001 : 2015 Certified Company

- Call Us: +91-9829083493 / +91-9829241529

Ball Mill Supplier in India

Ball Mill Manufacturers in India

BALL MILL WITH MICRONIZED PLANT

This is an effective Unit mainly for Calcite & Dolomite Minerals which carries out the process right from crushing of Stones Up to the Sizes of 6 mm to finally grinding. Jaw Crusher crushes the stone to the size up to 12 mm which is lifted by the Elevator and discharged in hammer mill. We are best Ball mill Supplier in India and also one of the leading Ball Mill Manufacturers in India.

Hammer mill reduce the product to -3mm and there is into Storage Hopper. From Hopper a Screw Feeder is provided with a Variable Frequency Drive to control the Feed of crushed material to Ball Mill. The ball Mill is having a Manganese Steel Lining and steel grinding media which-grind the material into fine powder. This powder is discharged through periphery of the Ball Mill.

Ball mills are a crucial equipment used in the chemical, pharmaceutical, mining, and food industries, among others, to grind materials to a fine powder. As among the leading Ball Mill Manufacturers in India we are committed to providing our clients with high-quality equipment to help them optimize their manufacturing processes. Our ball mills are a testament to this commitment. Our state-of-the-art ball mills are designed to deliver reliable performance, consistent particle size, and enhanced quality control, all while reducing energy costs and increasing productivity and serving all these refining features we are thus recognised to be the most reliable Ball Mill Supplier in India. In the following sections, we will discuss the features and benefits of our ball mills in greater detail.

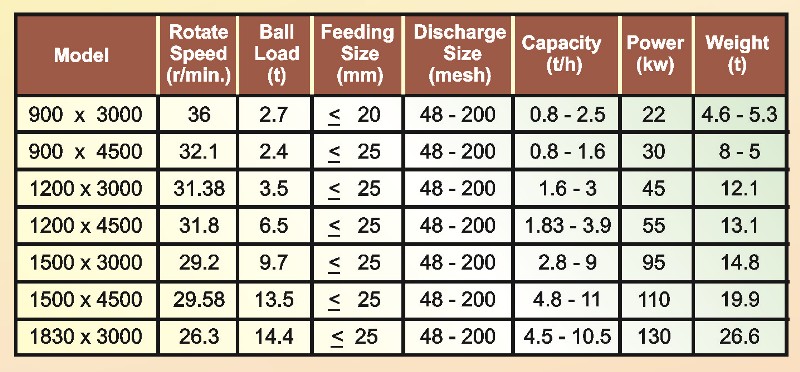

Technical Description